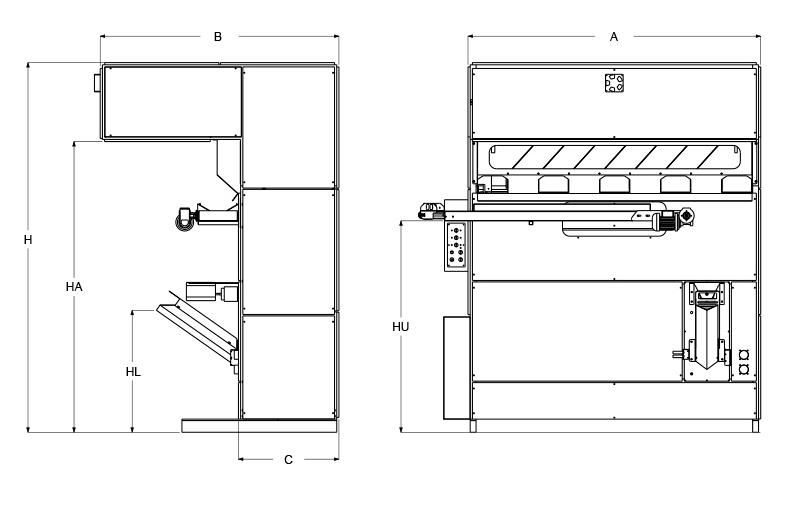

The CD is an extremely compact proofer, and requires a smaller space compared to the resting table used in the manual process. The pieces are loaded into trays with pocket, and each complete turn of the moving chain they are tipped over the next pocket. Once the last position is reached, the pieces come out at the opposite end of the machine. The number of trays required is calculated based on the desired hourly production rate and the required resting time. In the biggest 400 pockets version a resting time of 20 minutes can be reached, with a production rate of 20 pieces/hour of 300 grams maximum (see technical table for complete details).

The required number of pockets is determined based on the desired hourly production and rest time. In the larger version with 400 pockets it is possible to reach a resting time of up to 20 minutes with a production of 20 pieces/hour (consult the technical data for details of the achievable times).