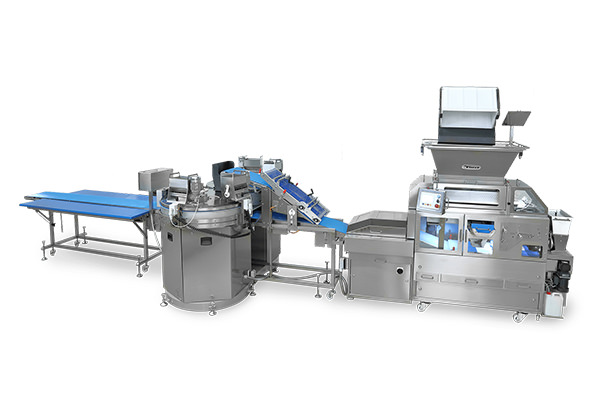

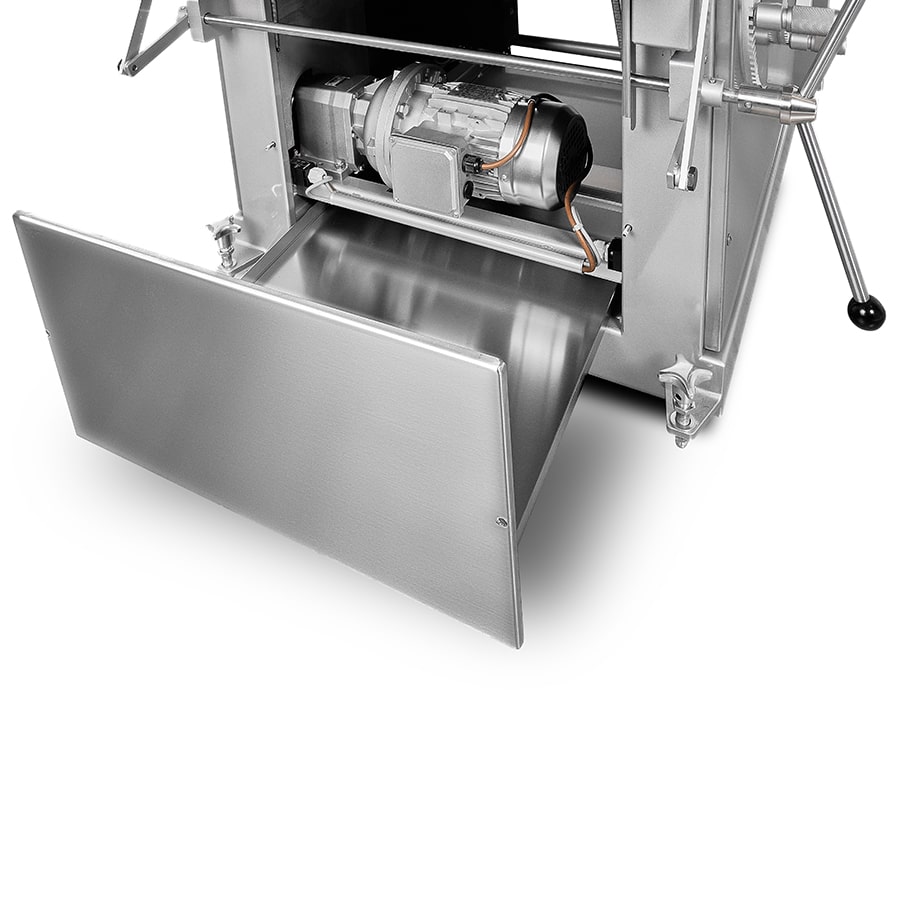

The upper rounding part of the machine can be used either separately from or combined with the lower moulding part, by simply shifting a switch. The movable bell eccentricity of the rounder can be adjusted, as well as the roller and moulding-table position, to ensure the highest precision for the whole process. The machine is available in the following versions:

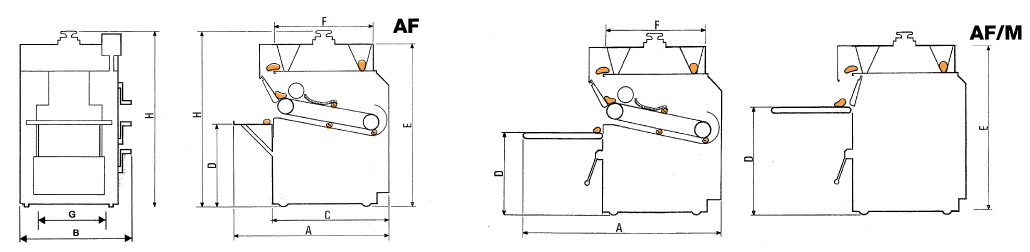

– AF with a 78 cm diameter bell and a fixed table on the moulder exit side

– AF/M with a 78 cm diameter bell and a movable conveyor belt that carries the round loaves in the upper position, and the long loaves in the lower position

Both models are available in the increased diameter version of 102 cm (models AFG and AFG/M), in order to obtain a greater rounding effect.

The perfect combination of the two machines and their high productivity with up to 1.800 pcs/hour results in both time and space savings to complete the moulding process.