THE CUSTOMER

Bäckerei Hänggi

• Third generation family business founded in 1949

• Modern and brilliant production in Rothenburg LU

• Five stores in the Lucerne area

• Supplying a demanding and diverse customer base in the cantons of Lucerne, Schwyz and Zug

• 110 motivated employees

• Production and delivery 365 days a year

• Ability to place orders through various channels, including the webshop

INITIAL SITUATION

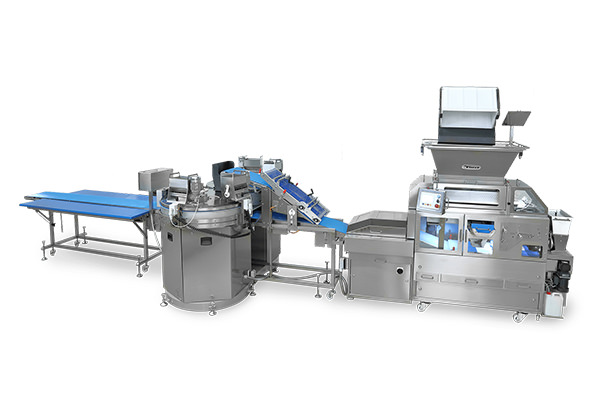

Initially, all our rounded breads were worked entirely by hand. The main goal was to find a solution that would lighten the workload of our employees without affecting the quality of the products or making changes.

GOALS

• Maintain bread production in an artisanal way, similar to manual labor.

• Eliminate the use of oil as a non-stick agent.

• Integrate other machines already present in the laboratory, such as a special roller with variable length.

CRITICAL ISSUES TO BE RESOLVED

• The manufacturing solution had to be compact to fit the limited space available.

• Compare performance parameters with all machines.

• Synchronize interfaces.

APPROACH

• Inclusion of all products in the production line.

• Detailed analysis of the current product manufacturing process, with productivity measurements.

• Creation of specific automation systems for each product.

• Further control phase to ensure quality, performance and optimization.

RESULTS

Now, the production of bread and rolls is fully automated, while ensuring consistent quality. All customer requests in terms of production features were successfully met thanks to the implementation and support provided.